When determining your business's manufacturing needs, it is important to choose the right products for the job. When it comes to adhesives, you need a product that meets the right requirements in terms of strength, environment, application, and your budget. Failure to choose the right product could be disastrous, especially when it comes to certain applications.

When deciding between retaining compounds versus threadlockers, it is important to first understand what the two are.

Retaining Compounds

A retaining compound is a type of adhesive used to fill the space between mechanical components as well as secure bearings inside houses, shafts, and retaining cylinder liners. They create a strong bond and typically have good resistance to harsh environmental factors.

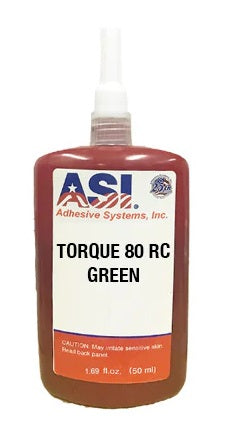

There are various retaining compound products designed to meet different application needs, but they are commonly used in the automotive industry or with heavy machinery. For example, the ASI Torque 80 RC has a short open time and allows for larger machining tolerances. In contrast, the ASI Torque 40 RC has a long open time to allow for more adjustments. The right product for you will depend on your specific needs.

Threadlockers

On the other hand, a threadlocker is a type of adhesive designed to lock threaded fasteners in place as well as protect them from leakage, shock, vibration, and corrosion. They can be a good alternative to traditional mechanical washers that can become loose or corroded over time.

A diverse collection, there are both general-purpose products as well as those with more specific applications. The Henkel Loctite 2046, for example, is designed to be used on food processing equipment and is compliant with indirect contact with food products. In contrast, the ASI Torque 42 TL is a general-purpose adhesive that can have many different applications but is not made to come in contact with food or food products.

Comparing Retaining Compounds Vs. Threadlockers

When comparing threadlockers versus retaining compounds, it is important to understand their similarities and differences. One similarity between the two is that they are both used in various industries where metal bonding is involved. Both are also anaerobic adhesives meaning they are one-part adhesives that only cure in the absence of air.

While they have similarities like with their chemical properties, they also have many differences. The biggest differences between retaining compounds and threadlockers are their applications and strength. Retaining compounds are meant to bond substrates and have a higher strength than threadlockers. In contrast, threadlockers are designed to protect fasteners and tend to have a lower strength capacity.

Can I Use a Threadlocker as a Retaining Compound?

Sometimes manufacturers will want to use a threadlockers as a retaining compound because of cost or other requirements. Whether or not this is a feasible alternative will depend on a few things such as the specific substrates, application, and the strength needed for the adhesive. In some cases, a threadlocker will do, but especially in terms of heavy machinery applications, the higher strength of a retaining compound may be recommended for the job.

Although you may now have a better idea of the similarities and differences between retaining compounds versus threadlockers, you may still be unsure which product to choose for your particular job. Do not worry. We want to help.

Our adhesives experts can guide you to finding the right product for your business. Just fill out our contact form and one of our adhesive experts will contact you. Not only can they help you find the best retaining compound or threadlocker for your specific needs, but also they may be able to provide you with other cost-saving adhesive solutions.