Updated: July 14, 2025

Jump to:

- Types of Mixing Elements

- Static Mixer Connection Types

- Types of Static Mixing Tips

- Choosing the Right Type of Static Mixer

- Product Recommendations

What Are Static Mixing Nozzles?

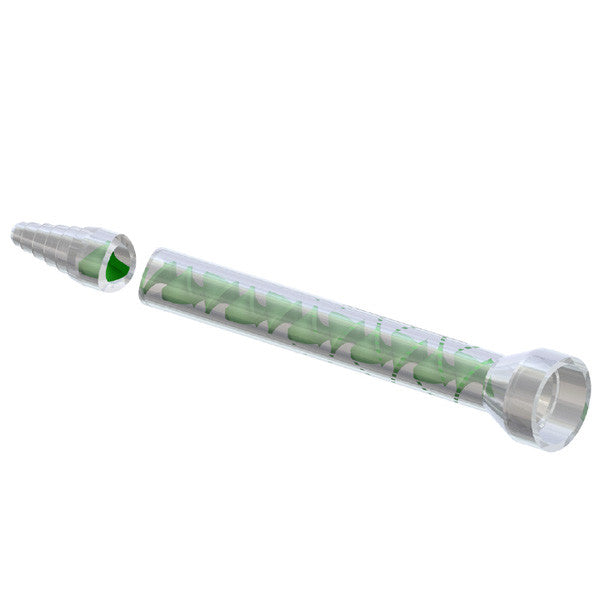

Static mixing nozzles, also sometimes referred to as static mixer tubes or static mixing tips, are a dispensing tool for two-part adhesives that use stationary components called elements to mix the two parts together into a homogenous mixture as they make their way down the chamber before being dispensed. This mixing process often activates the adhesive or material being dispensed and begins the adhesion process.

Static mixers attach to hand-held or meter mix dispensing equipment and are designed to be thrown away after each use. Their composition, including their number of elements, length, tip, and cartridge compatibility, can vary greatly depending on the needs of the application. There are also many different brands of static mixers. Several have similar or almost identical compositions, but in some cases, a brand will have a unique design.Consequently, understanding and choosing the right mixer can be challenging, but we want to help by breaking down the different components and offering some product recommendations.

Types of Mixing Elements

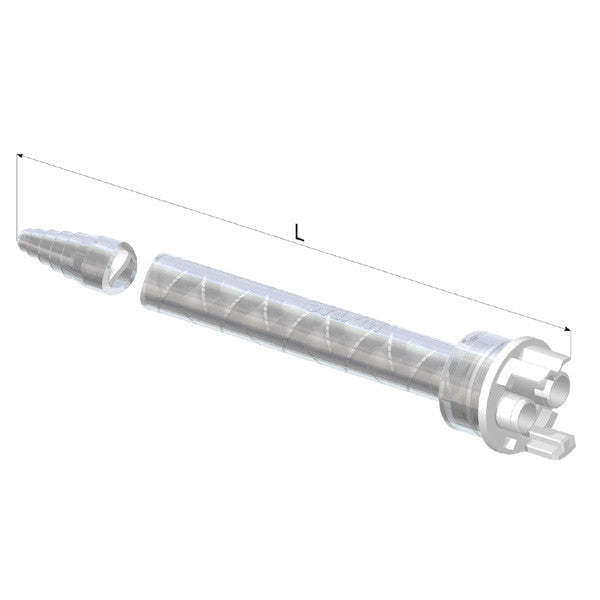

Mixing elements are the stationary structures found inside that mixer that are used to blend and mix the two components together as it is pushed through the nozzle. These elements can come in several designs.

Helical mixing elements - The traditional setup, helical elements have alternating orientations for a spiral-looking design and round nozzle.

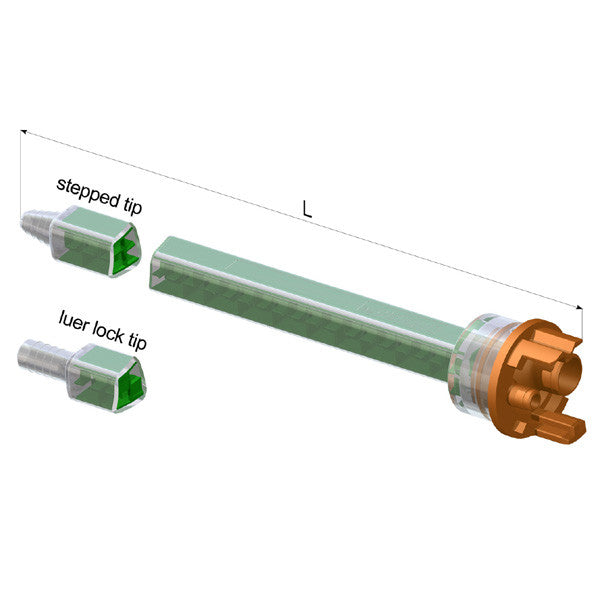

Quadro mixing elements - Quadro or square mixing nozzles are growing in popularity. They have a square shape grid design and require a shorter distance to provide the same efficient mix.

While these two designs are the most common, some brands have created their own style of mixing elements that can include a combination of the two or other geometric designs.

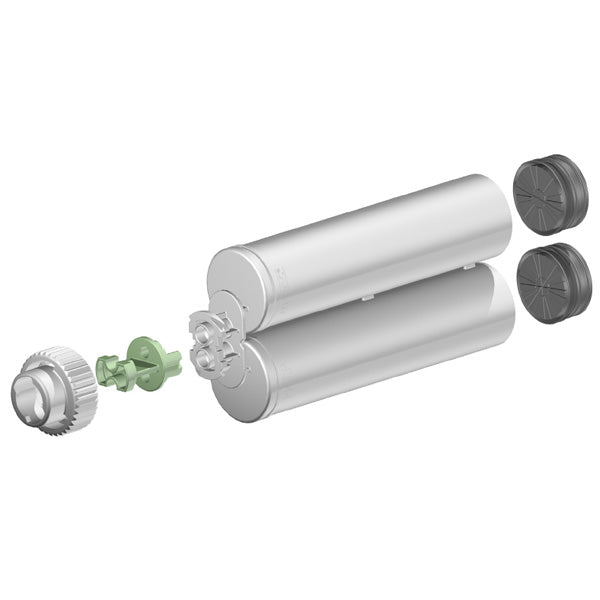

Disposable Static Mixer Connection Types

There are a number of different ways to connect a disposable static mixer to your cartridge or meter mix equipment. The most common static mixer inlet types are bell, bayonet, and integral nut.

Bayonet Connection - This rectangular connection is a twist and lock setup that is common for cartridge glue guns of all sizes.

Bell Connection - This type of static mixer connection will attach to a glue gun or more commonly, meter mix equipment using a retaining nut. After the nozzle is attached, the nut will slip over the top and screw into the equipment or gun.

Integral Nut (Threaded) - Typically used for larger cartridge sizes, these static mixer connectors have a threaded end that can be screwed directly onto the cartridge without the need for a retaining nut.

Some brands have their own connection types. The Sulzer (Medmix) B system and F systems, for example, are generally not compatible with other systems.

Types of Disposable Static Mixing Tips

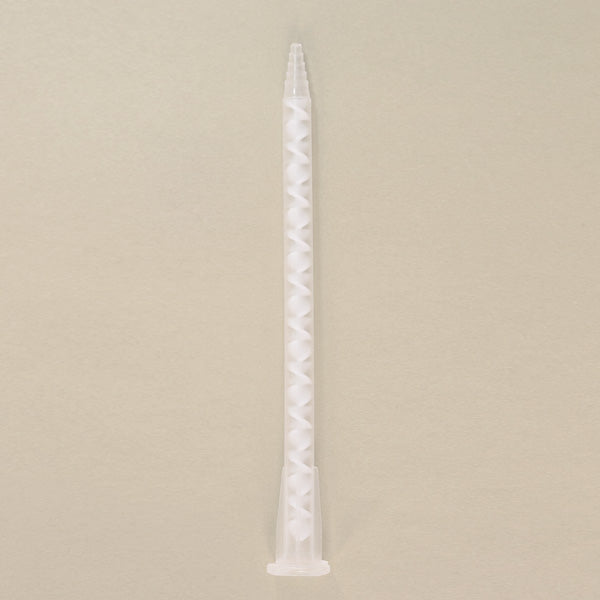

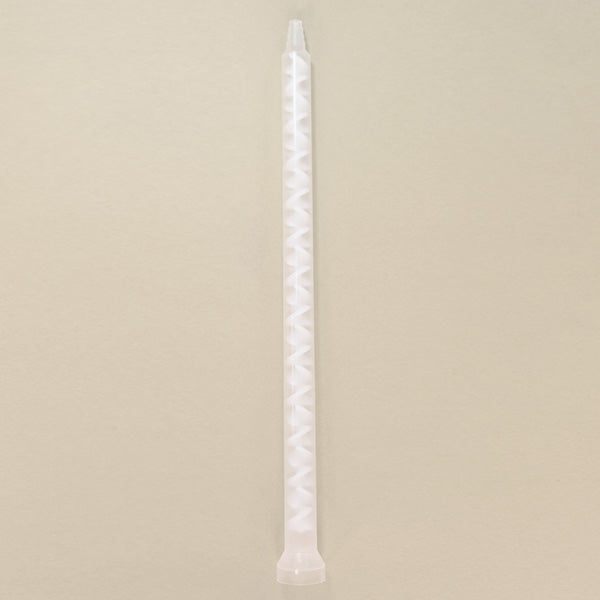

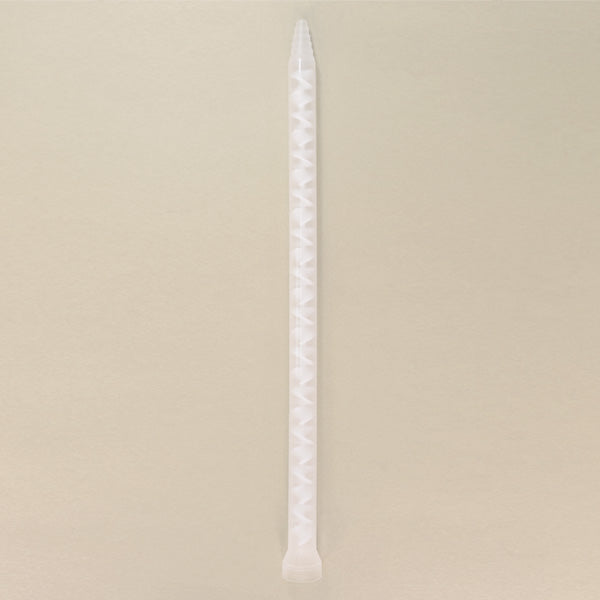

There are also several different static mixer tips to fit different dispensing needs. The three most common mixer outlets are stepped, tapered, and Luer lock.

Stepped Tip - These tips can be cut at various points to increase the size of the adhesive bead being dispensed. The ends don't require any adapters or needles to adjust bead size. The downside comes when fine dispensing is required.

Tapered Tip - Tapered tips are not adjustable, and for the most part, will not accept needles or fine tips. This is a simple and easy way to dispense common bead sizes.

Luer Lock - Luer lock tips give users the ability to add adhesive needles or tips for precise dispensing. Often, this type of disposable nozzle style requires an adapter like the Sulzer Mixpac LA 05-00 Luer lock adapter. After the adapter is attached, the needles and tips can easily be locked into place.

Full Bore - With a wider opening, a full-bore outlet is ideal for high-viscosity materials.

Choosing the Right Type of Mixer

You want to ensure that you get the right mixer for your specific requirements. The type of static mixer nozzle you need will depend on a number of different factors.

Type of Connection - Different cartridges and dispensing equipment use different connectors. Users should always start with the type of connection required.

Dispensing Equipment - One key consideration is if the adhesive will be dispensed by a machine or a hand-held applicator. Disposable mixers are more frequently used for hand-held equipment and are compatible with various cartridge sizes. Machine dispensing applications may also use static mixers if adhesives are being changed or other mixing options aren't feasible.

Type of Material - The materials you are mixing help determine the number of elements needed. Some materials are considerably more difficult to mix than others, so they require a higher number of elements in your mixer. The mix ratio of the material will also impact the number of elements required to achieve a homogenous mix.

Viscosity - Thicker adhesive components require larger diameter openings to flow and mix properly. The difference between component viscosities will also affect the number and type of elements needed. If the two elements have very different viscosities, you will likely need to use a higher number of elements.

Shot Size - A larger shot size/faster dispensing will require fewer mixing elements and a larger diameter opening. Because a larger diameter usually means less efficient mixing, a balance is required between the two. Smaller shot sizes require more mixing elements and a smaller diameter for an ideal mix.

Size - You will also need to figure out what size cartridge or meter mix equipment you will be dispensing from. This will help determine what type of mixer nozzle you need.

See our guide for more information: How to Choose a Static Mixing Nozzle

Product Recommendations

Even if you know what type of static mixer you are looking for, there are several similar products available on the market. As experts in the adhesive industry, we are sharing some of our recommendations for products based on various properties.

Jump to:

- For 50 mL Cartridges

- For 200, 400, & 600 mL Cartridges

- For Meter Mix Dispensing

- For Rotary Machine Dispensing Equipment

For 50 mL Cartridges

50 mL cartridges for are popular and a great way to mix and dispense two-part adhesives for low-volume applications or those that require lightweight, precise application of material. There are two types of 50 mL cartridges, each of which requires a different type of mixer nozzle.

1. Bayonet Static Mixers for 50 mL Cartridges (A-System)

Cartridge System

The Sulzer Mixpac A-System 50 mL cartridge kit comes in a variety of cartridge types and mixing ratios. They can be dispensed with most standard cartridge guns and provide a top-of-the-line solution for two-part dispensing.

Mixing Nozzle

The Infinity Bond Bayonet static mixing nozzle is the go-to mixer for two-part 50 mL cartridges. High quality and low cost make this static mixer the perfect match when dispensing epoxies, acrylics, urethanes, and more.

Mixing Nozzle

The Sulzer MAH Series bayonet mixers has a twist and lock mount for 1:1 and 2:1 dispensing. Locking the mixer into place automatically aligns the first element when using the Sulzer A System Kit.

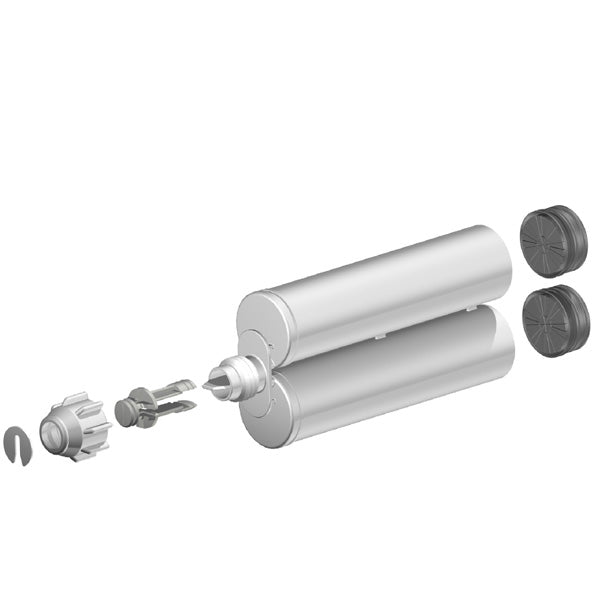

2. B-System Mixers for 50 mL Cartridges

Cartridge System

The Sulzer Mixpac B System 50 mL cartridge system offers a built-in piston retention for easier use. The rectangular back on the cartridge allows it to fit standard 50 mL cartridge guns, and it comes in a variety of configurations to better fit users' dispensing needs.Mixing Nozzle

The Sulzer Mixpac MBH 05-20T static mixer is a high quality mixer for dispensing 2:1 adhesives and materials. It utilizes a stepped tip giving users the ability to adjust bead size by cutting the tip. This mixer has 20 elements with a 5.4 mm element diameter and a twist and lock system for connecting to your cartridge.

Quadro Nozzle

The Sulzer Mixpac MBH 05-20T static mixer allows for optimal mixing between 1:1 and 2:1 two-part epoxies, silicones, acrylics, urethanes, and more. The Quadro form lets users get closer to the materials they are bonding.

Twist and Lock Nozzle

For 200, 400, & 600 mL Cartridges

Larger cartridges are a great option for medium- to high-volume dispensing applications. There are two types of larger cartridges, and each requires a different type of mixer nozzle.

1. C System Nozzles for 200 mL Cartridges

Cartridge System

The Sulzer Mixpac C System 200 mL cartridge system can be filled with most two-part adhesive materials that need to be mixed to activate. A nozzle can then be attached to the cartridge system to dispense the material using standard 200 mL manual or pneumatic guns.

Mixing Nozzle

The Infinity Bond 160-824 static mixer nozzle is the top-selling mixer for standard 1:1 or 2:1 adhesive dispensing from 200 mL or 400 mL cartridges. It is a bell mixer with a stepped tip allowing it to be cut at different sizes to adjust dispensing volume.

Mixing Nozzle

The Infinity MCH 10-24T static mixer is equal (or higher) in quality to its name-brand equivalents but offers exceptional cost savings. This mixer has a bell connection and stepped mixing outlet, so it can be cut to adjust the dispensing volume.

2. F System Static Nozzles for 200 mL Cartridges

Cartridge System

The Sulzer Mixpac F System 200 mL cartridge system allows for medium- to high-volume dispensing and includes self-venting lip seal pistons for easier extrusion as well as preassembled nose plugs. This cartridge is available in two different materials to better fit the materials being filled and dispensed.

Mixing Nozzle

The Sulzer MFH static mixers feature a unique outlet that connects the nozzle to the cartridge. This patented design is unique to Sulzer and allows the two materials to enter the nozzle through their own orifice to completely eliminate the possibility of cross-contamination. These mixers are used for dispensing 1:1 and 2:1 ratio adhesives.

Quadro Nozzle

3. F System Nozzles for 400 mL Adhesive Cartridges

Cartridge System

Mixing Nozzle

What makes the Sulzer MFH static mixers unique is the outlet that connects the nozzle to the cartridge. It allows the two materials to enter the nozzle through their own orifice. This design eliminates the possibility of cross-contamination.

Quadro Nozzle

For Meter Mix Dispensing Equipment

Meter mix equipment is perfect for high-volume applications, and Bell static mixing nozzles are a high-quality, low-cost solution for a wide variety of these applications.

Mixing Nozzle

One of the most tried and true mixers for two-part dispensing with meter mix equipment, the Sulzer MS Series static mixers are a great choice.

Mixing Nozzle

For Rotary Machine Dispensing Equipment

Nozzles for rotary machine dispensing equipment are designed for use with specialty meter mix and dispensing equipment. Static nozzles provide inexpensive solutions for dynamic mixing with elements that rotate within the nozzle attachment.

Mixing Nozzle

Find the Right Type of Static Mixing Nozzle

Choosing the best static mixer for your application is a process. While you may now have a better understanding of the different types of static mixers, you may still want to consult one of our adhesive experts. You can also visit our collection of static mixing nozzles and shop for yourself.